Acquisition of a CNC punching press

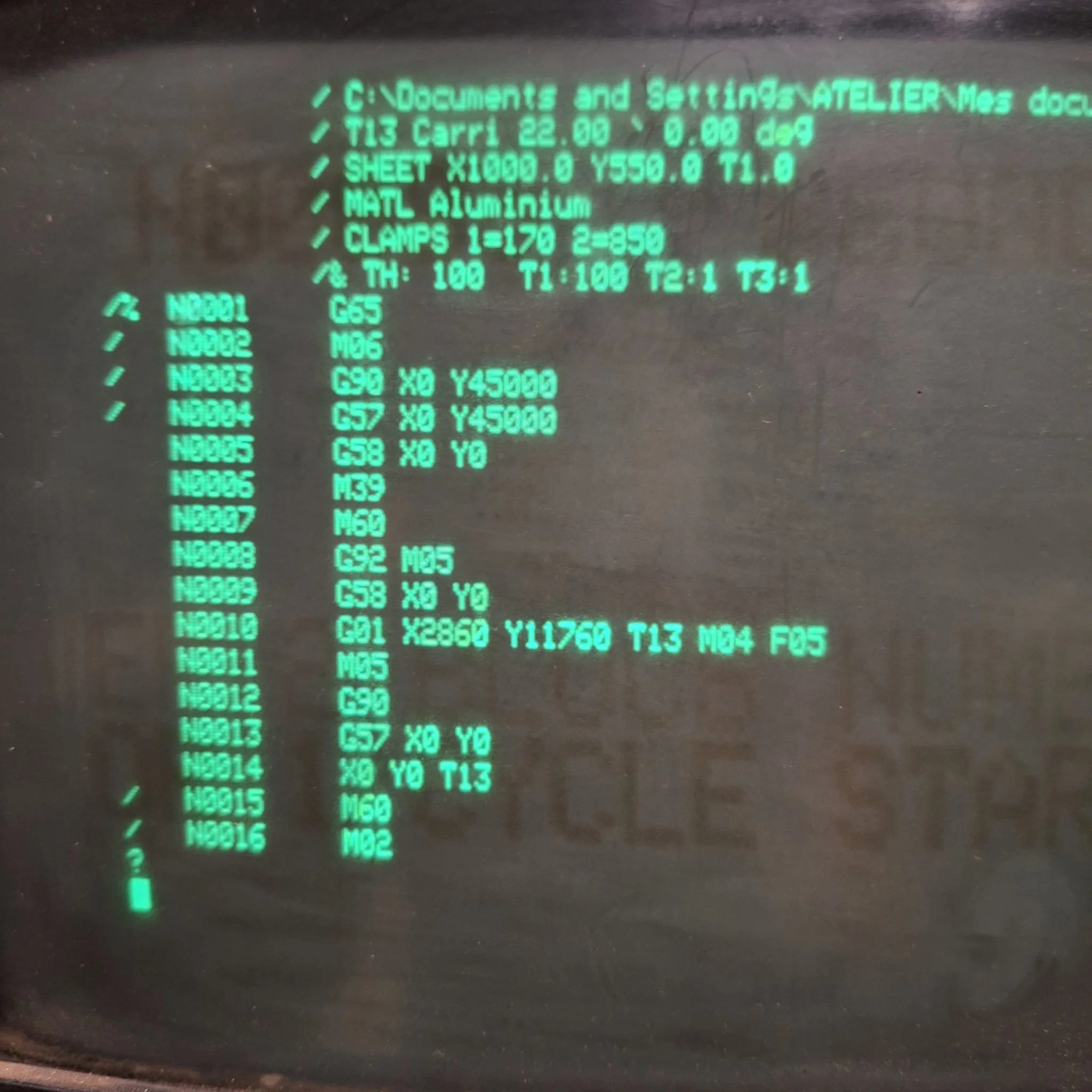

Halfwerk acquires a vintage numerical punching press that is suitable for cutting sheetmetal up to 6mm thick. Despite its age, the machine offers considerable advantages over lasercutting, in particular for the transformation of salvaged steel. We often don’t know the precise composition of the metals we use, and typically our raw materials are already coated with paint or other metals. Because punching is a cold transformation process, it is not bothered by such impurities. Further more, the considerable lower cost of investment in the machine allows for a more relaxed use compared to state of the art equipment. This is fundamental for our experimental approach to steel reuse.